ASU, LNG Liquefaction Plant, CO2 Capture Plant, N2O Production Plant, H2 Plant etc

H2 plant Hypower Project wind power to H2 2000NM3 per hour (1).jpg)

.jpg)

.jpg)

Industrial Gas Equipment Needs?

Expertise in Industrial Gas Equipment

With two decades of experience, we have mastered the art of designing and manufacturing cryogenic plants and equipments

State-of-the-Art Facilities

Our advanced production facilities and rigorous quality control processes ensure that every product meets the highest standards.

Customization Options

Competitive Pricing

As a factory-direct manufacturer, we provide cost-effective solutions without compromising on quality.

Global Reach

Our products are trusted by clients worldwide, and we have the expertise to meet the demands of diverse markets.

Reliable Support

From product development to after-sales service, our dedicated team is here to support you every step of the way.

Partners

What products I can order from your company?

As a leading manufacturer in China, we mainly produce and supply following equipment:

- Cryogenic air separation plant

- LNG liquefaction plant

- VPSA/PSA Oxygen Generator

- CO2 recovery plant (automatic control, manufacturers remote monitoring)

- N2O production plant

- Hydrogen production plant (Water Electrolysis,WE)

- Cryogenic liquid storage tank (LO2, LN2, LAr, LCO2, LNG and LPG)

- ISO tank, Semi-trailer tanker

- Vaporizer and cryogenic liquid pump

- Gas filling Station, Cylinder, Compressor

- Dry Ice machine etc.

- Dewar flask & micro bulk tanks

- Standard gas

- Hydrogen gas storage cylinder and ISO transport tank

- gas purifier

-Differential pressure compound transmitter to monitor liquid level, pressure with 4G wireless remote

What is your production standard? Can you manufacture your products under ASME standard?

Our products are designed, manufactured and tested as per reference standards of GB150, Safety technology supervision regulations of pressure vessels and some other reference Chinese standards.

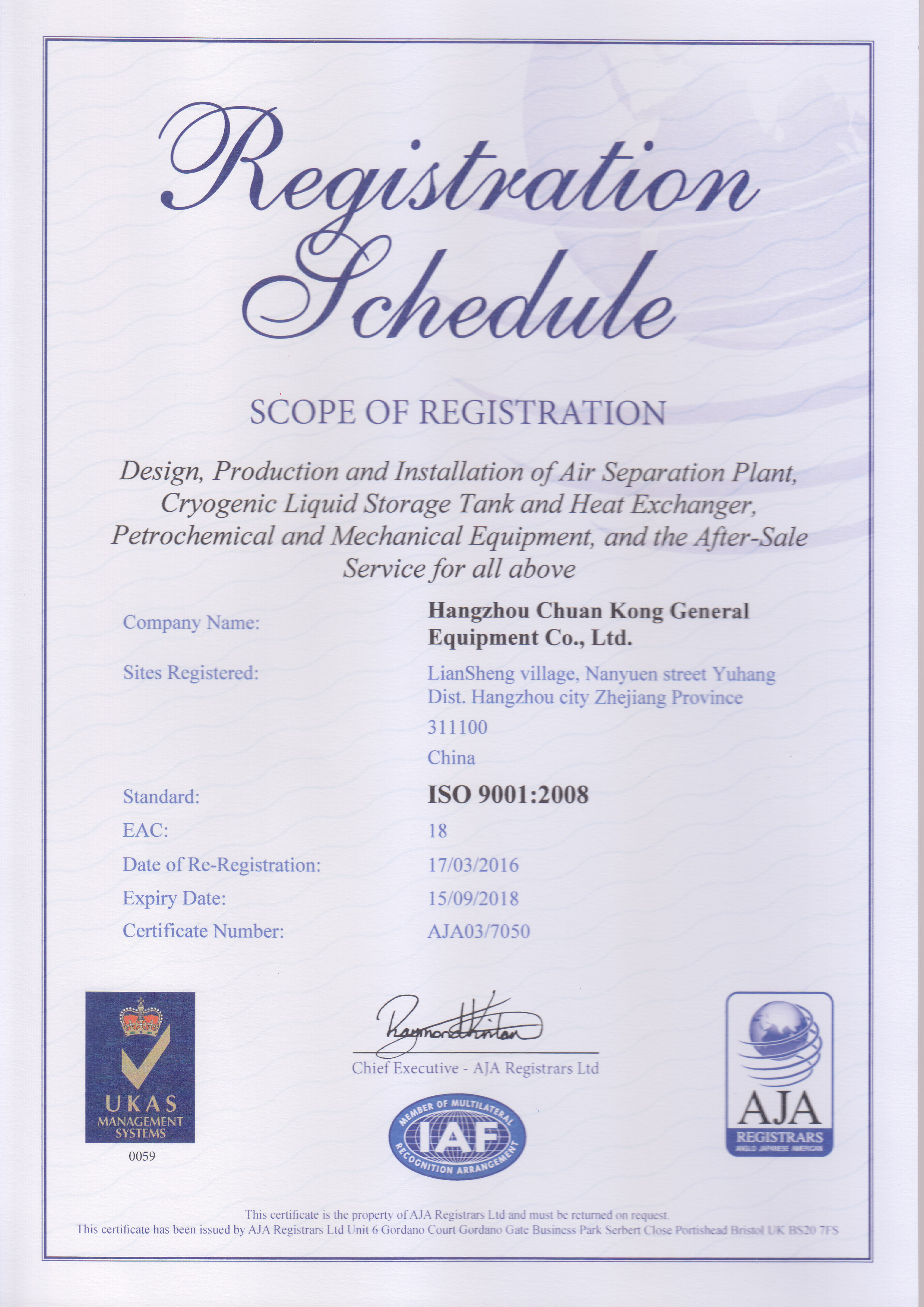

Our company has obtained the A2 and C2, C3 Pressure Vessel Fabrication Certifcates ,Grade GC1 Pressure Pipe& Vessel Construction Certifcates, ISO9001 Quality Certificate, ASME Certificate and U Stamp. So, if you ask for ASME stamp, we are able to manufacture your products under ASME standard.

Have you supplied tanks to any renowned companies?

We are a regular strategic partner of some big gas companies, such as Messer, Boc, Air Product and Air Liquide, etc in China. We have supplied many storage tanks for them with different sizes. The biggest size we ever provided is 3000m3 ordinary pressure storage tank. We also made high pressure storage vessels for them, such as 5~200m3. Meanwhile, we are one of the long-term storage tank suppliers for Pepsi and Coca-Cola in China.

Can you provide the drawings of your cryogenic plants and equipments?

Normally, our drawings will be provided to our customer only after the order is confirmed. However, we can provide you some drawings which belong to our old customers for reference. By the way, here, I need to remind you that our company only provides the engineering design drawings and the civil design drawings will be out of our range. Because every place has different situation, your side needs to find civil design company in your local market to do the drawings according to your specified environment.

For us, our scope of supply includes:

- plant design

- supply of the whole set of plant

- sea transportation

- installation of plant (optional item)

- debugging of the plant

We don't include the civil engineering & public works. Often we don't include installation of plant, but we send engineer for supervision of installation at cost.

support you with

professional feasibility

analysis and solutions.

1.png)