Our Advantages

OUR ADVANTAGES

- Large production capacity and output

- Advanced production facility and up-to-date technology

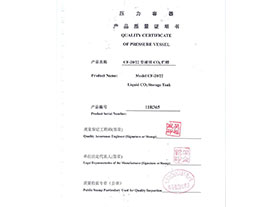

- Complete testing and quality assurance system

- Scientific management

- Cost-saving sourcing of raw materials and spare parts

- Sound packaging and timely delivery

- Professional sales and service support

- Excellent team work

1.1Large production capacity and output

150 TPD ASU Cold Box to be Delivered in the Workshop

150 TPD ASU Cold Box to be Delivered in the Workshop 25000NM3 ASU Cold Box Installation

25000NM3 ASU Cold Box Installation Cryogenic Liquid Pump Workshop

Cryogenic Liquid Pump Workshop Dewar Flask Finished Products

Dewar Flask Finished Products Dewar Flask Workshop Semi-finished Products

Dewar Flask Workshop Semi-finished Products Dry Ice Making Machine Workshop

Dry Ice Making Machine Workshop Dry Ice Making Machine

Dry Ice Making Machine Dry Ice Storage Bin

Dry Ice Storage Bin Storage Tank Workshop 1

Storage Tank Workshop 1 Storage Tank Workshop 2

Storage Tank Workshop 2

1.2 Advanced production facility and up-to-date technology:

160T Crane

160T Crane aluminum alloy internal-external combination longitudinal-circumferential welding system(USA)

aluminum alloy internal-external combination longitudinal-circumferential welding system(USA) Aluminum Tube Automatic Argon Arc Welding Machine

Aluminum Tube Automatic Argon Arc Welding Machine Automatic Pipe Bending Machine

Automatic Pipe Bending Machine Automatic Welding Machine

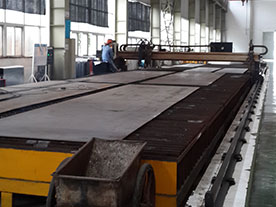

Automatic Welding Machine CNC Underwater Plasma Cutting Machine

CNC Underwater Plasma Cutting Machine Edge Planner

Edge Planner Five axis digital control milling machine

Five axis digital control milling machine Steel Plate Cutting Machine

Steel Plate Cutting Machine Steel Plate Rolling Machine

Steel Plate Rolling Machine Steel Plate Rounding Machine

Steel Plate Rounding Machine Vacuum Pump

Vacuum Pump Welding Machine

Welding Machine Cylinder Workshop

Cylinder Workshop Dewar Warehouse

Dewar Warehouse

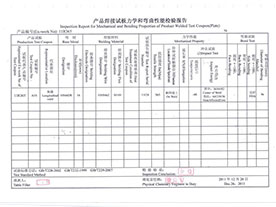

1.3 Complete testing and quality assurance system

Electro-hydraulic Servo Universal Testing Machine machine

Electro-hydraulic Servo Universal Testing Machine machine Flaw Detector

Flaw Detector Fluid heat transfer laboratory

Fluid heat transfer laboratory Helium Mass Spectrometer Leak Detector

Helium Mass Spectrometer Leak Detector Hydraulic Test Fixture

Hydraulic Test Fixture Material Mechanics Tester

Material Mechanics Tester NDT Room for Dewars

NDT Room for Dewars NDT Room for Storage Tanks

NDT Room for Storage Tanks Spectrometer

Spectrometer Vaccum Gauge

Vaccum Gauge

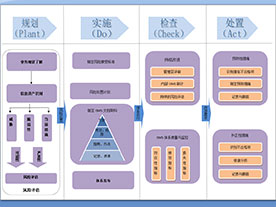

1.4 Scientific management:

Our workshop practices 5S management. Timely detection and immediate solution of problems are required in our workshop.

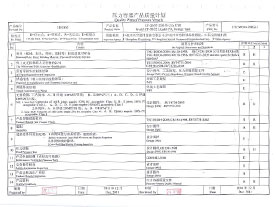

1.5 Cost-saving sourcing of raw materials and spare parts:

As a top brand in the market, we have been in partnership with many first class factories of steels, stainless steels, instruments, valves and pipes. In order to reduce cost and assure quality, we directly buy raw material from manufacturers. All the raw materials have their manufacturer’s warranty. Plus, double checks shall be conducted upon arrival of raw material to ensure that they conform to our requirement. By doing this, we guarantee both the best price and the finest workmanship.

1.6 Sound packaging and timely delivery:

20m3 LOX Tank being Fixed on Container

20m3 LOX Tank being Fixed on Container 100TPD ASU Spare Parts for Air Product

100TPD ASU Spare Parts for Air Product 25000NM3 Per Hour ASU Cold Box for Indonesia Loaded on Barge

25000NM3 Per Hour ASU Cold Box for Indonesia Loaded on Barge Container Leaving Factory after Loading Storage Tank

Container Leaving Factory after Loading Storage Tank Container Seal in the Factory

Container Seal in the Factory External View of Built-in Private Wharf

External View of Built-in Private Wharf Fully Packed Storage Tanks

Fully Packed Storage Tanks Internal View of Built-in Private Wharf

Internal View of Built-in Private Wharf Valves and Insutruments Wrapped by Plastic

Valves and Insutruments Wrapped by Plastic Storage Tank Workshop 2

Storage Tank Workshop 2

1.7 Professional sales and service support:

Our products are exported to more than 40 countries and regions, including United States, Mexico, Turkey, Russia, Ukraine, Armenia, Malaysia, Pakistan, Vietnam, Philippines, UAE, Saudi Arabia, India, Taiwan, Iraq, etc. In marketing, we adhere to the concept of all for development and all for customers. We have 20 years rich experience in doing international sales. According to the contract, we can send engineers to customers’ site for installation supervision and technical training. Customers can receive life-long consultancy service even after warranty time.

1.8 Excellent team work

A variety of training activities are carried out regularly to improve working skills as well as cohesion and duty sense of our team. Every staff is regarded as a part of our strategies, missions and visions.